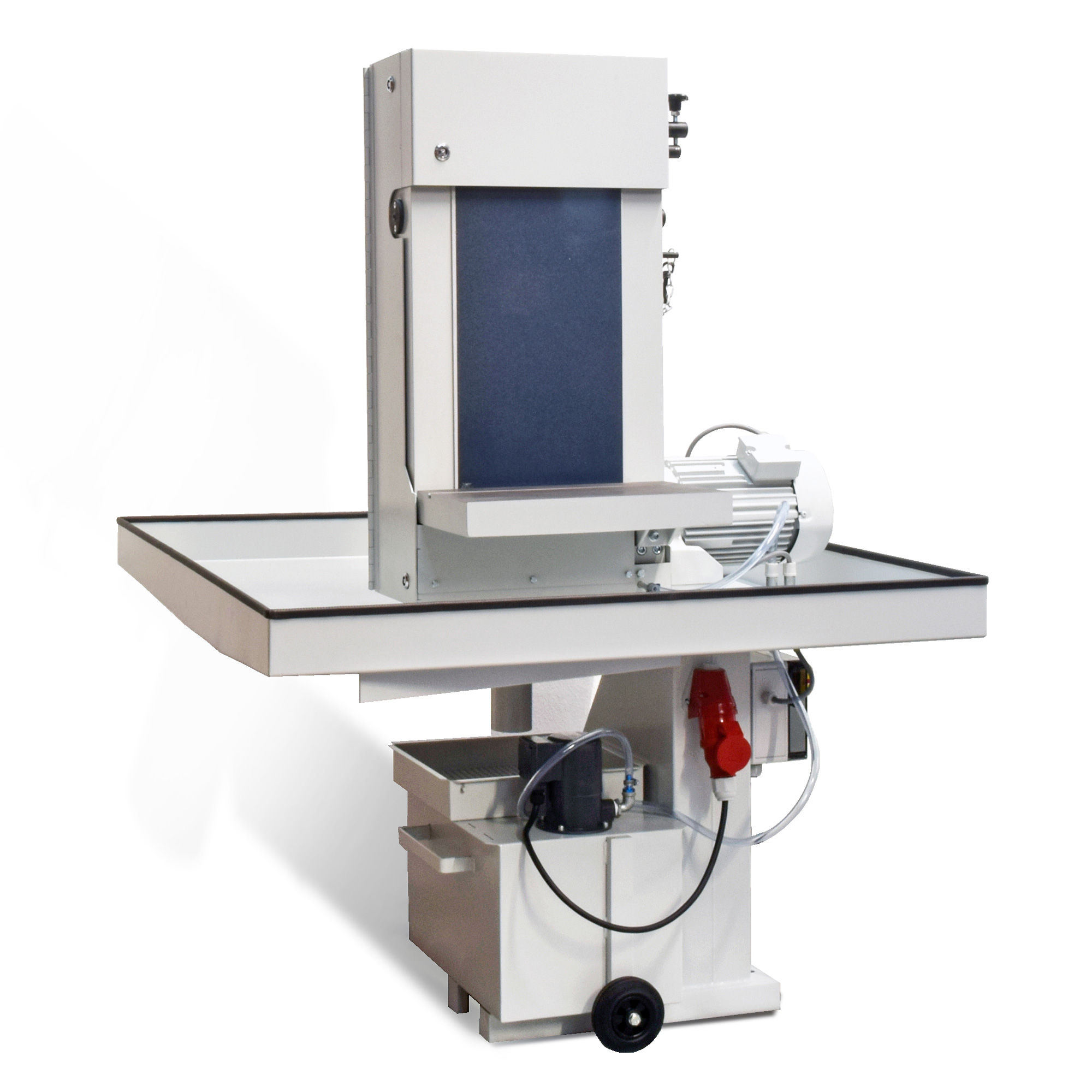

Surface belt grinding machines TYPE BS

Surface belt grinding machines – dry grinding

Surface belt grinding machines – wet grinding

Industry:

Metal construction, Automotive supplier, Aeronautical engineering, Tool making, Medical technology, Locksmith, Foundry, Contract grinder

Scope:

Stainless steel, high-alloy and unalloyed steel, non-ferrous metals, cast steel, aluminum, titanium, plastics, glass, paper, for components such as turbine blades or die-cast and investment castings

Delivery time: 6-8 weeks

Error: Contact form not found.

Technical data

Surface belt grinding machines – dry grinding

| Type | BS 75 | BS 200 | BS 300 |

| Motor | 0,55 / 0,7 kW | 1,5 / 2 kW | 3 kW |

| Number of revolutions | 1450/2900 U/min | 1450/2900 U/min | 1450 U/min |

| Cutting speed | 8/16 m/sek | 10/20 m/sek | 15 m/sek |

| Diameter | 100 mm | 132 mm | 200 mm |

| Sanding belt | 950 x 100 mm | 1500 x 200 mm | 2000 x 300 mm |

| Suction nozzle Ø (mm) closed. belt protection | 75 mm Ø | 100 mm Ø | 150 mm Ø |

Surface belt grinding machines – wet grinding

| Typ | BS 75-W | BS 200-W | BS 300-W |

| Motor | 1,1 kW | 2,5 / 3 kW | 4 kW |

| Number of revolutions | 2900 U/min | 1450/2900 U/min | 1450 U/min |

| Cutting speed | 16 m/sek | 10/20 m/sek | 15 m/sek |

| Diameter | 100 mm | 132 mm | 200 mm |

| Sanding belt | 950 x 100 mm | 1500 x 200 mm | 2000 x 300 mm |

| Tub dimensions length x width | 730 x 990 | 1050 x 850 | 1400 x 1200 |