Dust extaction units

Suction PC 04

Applications

Dust extraction for belt grinders

Special advantages:

Gallery

Type PC 01/TV-Q

Area of application

Extraction of grinding and polishing dust.

Classifying the dusts according to type,

particle size and concentration, it is possible to

determine the best possible technology and correctly dimension the filter system.

Special advantages

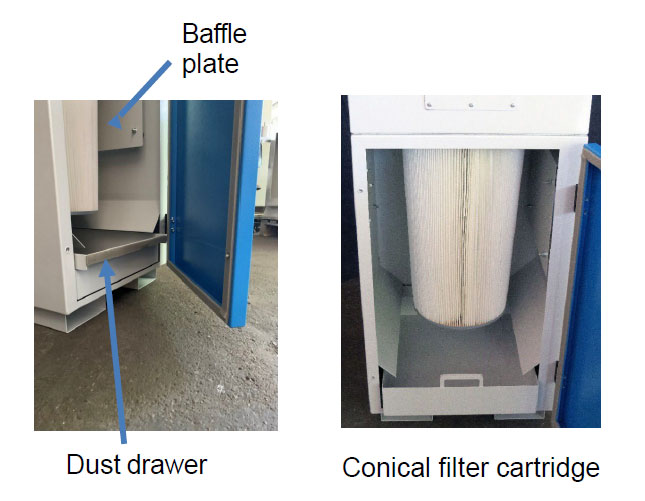

Description and mode of operation

The air to be treated flows into the filter (1) and enters a pre-chamber (1), which favours the separation of coarse pollutant particles. The airflow then passes through the filter cartridge (2) and deposits the contaminants outside the filter cartridge, while the clean air is discharged from the upper part of the filter (6). An electronic device (4) controls the cleaning of the filter elements (2) with a pulse jet system.

The pulse jet cleaning system consists of a counter-current injection of a high-pressure air flow to remove dust from the filterelements without interrupting operation. Correct cleaning of the filter fabric guarantees the flow of the air drawn in.

Technical data

| Motor power: | 1.1 kW |

| Filter area: | 10 m² |

| Extraction capacity: | 800 m³/h |

| Dimensions: | 500x500x1900 mm |